Menu

Everything You Need to Know About the History of the A-Clamp

Overview

Surgical clamps, also called hemostats or locking forceps, are used by many surgeons to compress blood vessels and stem the flow of blood or other fluids temporarily during surgery. In addition, clamps are used for many other purposes including tube occlusion and holding sponges, securing drapes, etc.

Clamps come in various styles for many different medical purposes and functions. One style is the straight A-clamp, an occluding clamp commonly used in dialysis, blood banks, veterinary medicine, and other medical applications. Provided by Dravon Medical, the A-clamp is a non-invasive medical device designed with smooth jaws for occluding 1 mm to 8 mm tubing without damaging it. Its unique reinforced nylon construction makes it lightweight and durable, while the aluminum rivet allows the clamp to be visualized on x-ray.

The History of the A-Clamp

The earliest clamps (hemostats) can be traced back to 1500 B.C. in ancient Egypt, as suggested by a drawing found on a tomb at Thebes. The drawing on this tomb shows a man lifting molten bronze in a circular crucible, using crossed wooden staves that look like a clamp.

Also, ancient scriptures at the time of Pompeii’s destruction in 79 A.D. depict Roman surgeons using various bronze pivot-controlled surgical instruments, probably for hemorrhoidectomy and uvulectomy. However for extracting teeth or molars, iron forceps were used since bronze ones were prone to bend or break.

The concept of clamping blood vessels to stem hemorrhaging was developed by Galen, a Roman physician who lived in the second century A.D. Illustrations by Albucasis, in the 9th century A.D., show pivoting forceps designed for tooth extraction. Later in 1868, a French surgeon named Jules-Emile Pean was credited with inventing the first rendition of modern forceps.

Throughout the centuries, surgical clamps have been through significant changes. The first models of clamps were made of metal and copper and designed in a curved shape for tooth extraction. Today, the current models of hemostats are composed of stainless steel.

The first modern vascular clamp was developed by Edmund Höpfner in 1903 at the Berlin University Hospital, Department of Surgery, as part of his doctoral thesis. This clamp was about 15 cm long with spring steel jaws separated in the middle and approximated toward the end.

Currently, medical device companies design and mass produce a variety of stainless steel surgical clamps. The function of these clamps is to occlude bleeding temporarily, thus giving time for surgeons to suture the bleeding vessels. Modern manufacturing techniques have also allowed for the design and mass production of plastic, disposable clamps as well for other healthcare applications.

The Technology Behind the A-Clamp

Vascular clamps are used to occlude blood vessels safely without causing any damage to the vessel wall. So, its basic design is based on three parameters:

- The clamp’s occlusive capacity means the clamp’s effectiveness in overcoming intraluminal fluid pressure.

- Holding ability: the clamp ability to perform well without slipping when applied to a transacted blood vessel

- Safety: The capacity of a clamp to occlude the lumen of the vessel without causing an injury to the vessels’ walls

Like vascular clamps, tube occluding clamps perform the same function (occlusion for blood or other fluid), but they’re not utilized on biological tissue. They’re applied on tubes carrying blood, saline, and other fluids to halt fluid flow temporarily. The ratchet teeth of the clamp hold the tubing closed, while its smooth plastic jaws protect the tubing from damage.

Who Uses A-Clamps?

Hospitals and medical clinics such as dialysis centers and blood banks widely use these clamps to control fluid flow in the flexible tubing during procedures. Additionally, these clamps are sometimes used as part of custom surgical kits for vascular procedures.

How to Use the A-Clamp

Major medical facilities trust the Dravon Medical True Blue A-Clamp. It’s used during dialysis and blood collection procedures, and other applications as well. The intended use is occlusion of 1 mm to 8 mm diameter PVC and silicone tubing.

A-Clamp Features

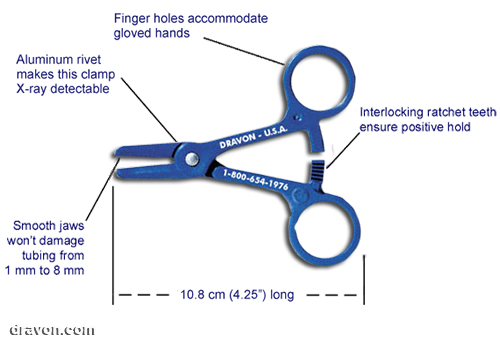

- Reinforced nylon material designed to be lightweight and durable

- Aluminum rivet allows clamp to be visualized on x-ray

- Smooth jaws designed to prevent damage to the tubing

- Interlocking ratchet teeth ensure a positive hold.

- Oversized finger holes for ergonomics

- Disposable clamp

- Made in USA

Dravon Medical is a medical device manufacturer that has been serving health facilities globally since 1974. We focus on ensuring that our A-Clamp is high quality, works reliably, and is easy to use.